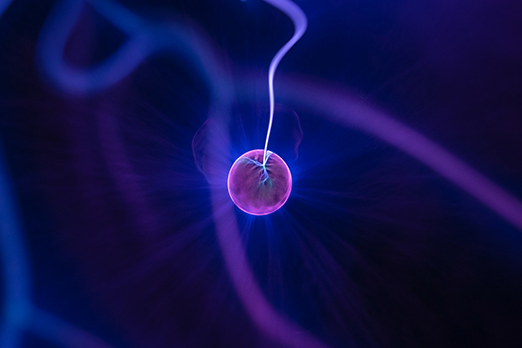

What is cold Plasma?

From school we know the three states of matter solid, liquid and gaseous. Plasma represents the 4th state of aggregation and can be generated by the ionization of gases. When cold plasma is generated, additional energy is added to the ambient air (i.e. the matter in gaseous state to the gas). In contrast to the "thermal" plasma, in the "cold" plasma practically "only" the electrons of the participating atoms of the participating matter are excited - the then positively charged atomic hulls, which contain the decisive mass, remain "cold" at first.

Here, "cold" is rather to be understood as "not hot". When applied to ambient air, such a stimulation ionizes the entire air - and everything in it like water, suspended matter, viruses, spores etc. - i.e. the atomic and molecular assemblies are dissociated (simply put, broken down into their individual parts) and the electrons are the first to be raised to new, much higher energy levels, where they do not really feel permanently comfortable. Therefore they look for the next best new partners and "recombine" to form new (molecular) structures and release the energy they received before. During such a recombination, however, the original atomic or molecular assemblies do not reappear, but mostly much less complex (and energetically lower) structures.

Cold plasma as a disinfection method in medicine

Cold Plasma uses this principle to "dissociate" complex viruses, bacteria, spores, etc. - i.e. to break them down into their individual parts and later "recombine" them into harmless low-energy new structures. The kind and mutation type of viruses etc. is irrelevant, it only has to fit "energetically" into the "prey scheme".

Cold, atmospheric plasma has been produced since the early 1990s. The first medical devices for disinfection and wound treatment have been approved since 2013. Therefore, cold plasma also has excellent properties: It stimulates the tissue to regenerate and strengthens the immune system .

What other applications for disinfection using cold plasma are conceivable?

Plasma only needs some electricity and air to work. Therefore disinfection methods for surfaces based on cold plasma are conceivable for many industrial purposes. This includes, for example, air and water treatment or surface disinfection. Plasma-based disinfection methods are particularly suitable here, as materials are not attacked. This also enables applications on temperature-sensitive surfaces, human skin or safety-relevant components made of rubber compounds.

The most important advantages over chemical disinfection methods are the pollution of the environment, undesirable by-products (DNP) or odors.

In addition, no resistance can be developed here by microorganisms.

In contrast to disinfection with UV-C light, cold plasma has no problems with shadowing. As a result, it is also suitable for use on uneven and amorphous surfaces.

How can cold plasma be integrated into these applications?

With Plasma-BOD. The special feature of the plasma-based surface disinfector is that it enables a chemical-free disinfection of surfaces of any kind.